Our Capabilities

We Offer You:

Custom Designed Closures

- Wide selection of tamper-evident closures

- Large range of standard SPI 400 closures: 28mm-120mm

- Large range of deep skirt closures: 33mm – 120mm

- Different thread styles

- Lip-seal, ‘V’ seal, flat seal, plug seal and dual seal options

- Embossing and debossing

- Wide range of lining materials available in tri-tab or round cut profiles

- In-mold label decoration

- Dispensing closures with and without valves

- Solid modeling (CAD), rapid prototyping, and production prototyping

- Safeguarding of intellectual property

Internal Product Design, Development, and Mold Building Capabilities

- Product Design and Development

- 50 years of closure design experience

- Customized closure design

- 3D modeling

- In-house SLA 3D model printing

- Selective Laser Sintered (SLS) models

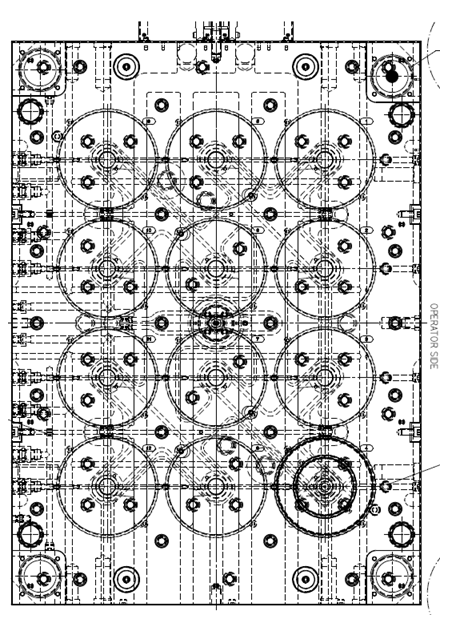

- Mold Building

- 30 years of closure mold design experience

- Modern and optimized mold designs for efficient molding

- Custom prototype molds

- Production molds

- Full Service Tool Room

- Comprehensive mold maintenance

- Mold modifications

Manufacturing Processes

- Cost effective manufacturing operations

- Molding machine size range 300 – 500 tons

- Lining machines for 15 – 120 mm

- Robotic assembly and packaging

- Vision system inspections

Customization Options

Embossing and Texturing

We offer customizable embossing and texturing. We ensure that each cap is unique to ensure every aspect of your product is perfect.

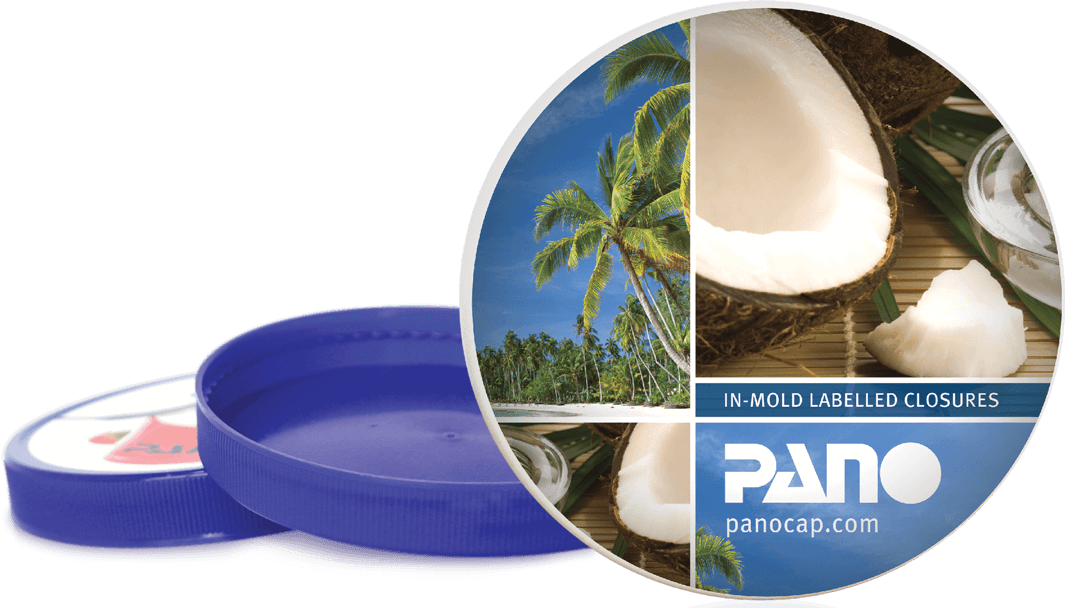

In-Mold Label Decoration

We ensure that with advanced custom molding and manufacturing processes your product label is printed with the newest technologies and molded onto your closure showcasing your finest brand marketing.

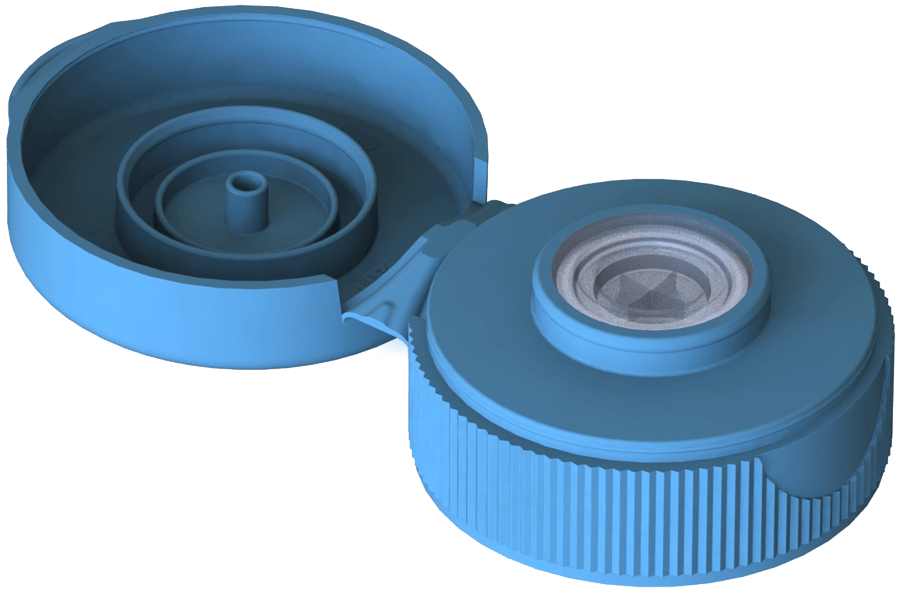

Dispensing Solutions

We offer a variety of customized solutions for your dispensing products. We offer a product line of dispensing plastic closures with or without valves. Our dispensing solutions are the perfect choice for all of your products.